Biohazard & Medical Waste is on the Rise

Biohazard Waste Management is a key player in today’s healthcare markets. This is derived from an increased amount of biohazard waste generated from all kinds of health care procedures and tests. We are all familiar with many, for example: COVID-19 tests, vaccinations for all variants, flu vaccines, shingles, blood tests, that generate all kinds of medical waste. The medical waste management market is increasing to $18B dollars by 2025.

Therefore, the increasing demand of health care services is simply catapulted by higher health care coverages and longevity. Hence, more health coverage and pandemics are generating massive increase of biohazard waste. As a consequence, this biohazard and medical waste demand creates a huge opportunity for innovative technologies and solutions. Market research reports indicate that:

The global medical waste management market is expected to grow from $14.17 billion in 2020 to $14.56 billion in 2021 at a compound annual growth rate (CAGR) of 2.8%. The market is expected to reach $18.18 billion in 2025 at a CAGR of 6%. Source: Global Markets

Besides that, COVID-19 has demonstrated that it is paramount to create solutions for biohazard waste management and cleaning devices, that are safe under highly contagious deseases and pandemics. As a result, the manipulation of highly contagious waste, like the one generated by Coronavirus, only makes the need to use other methods to handle processes with minimum contact more valuable and marketable.

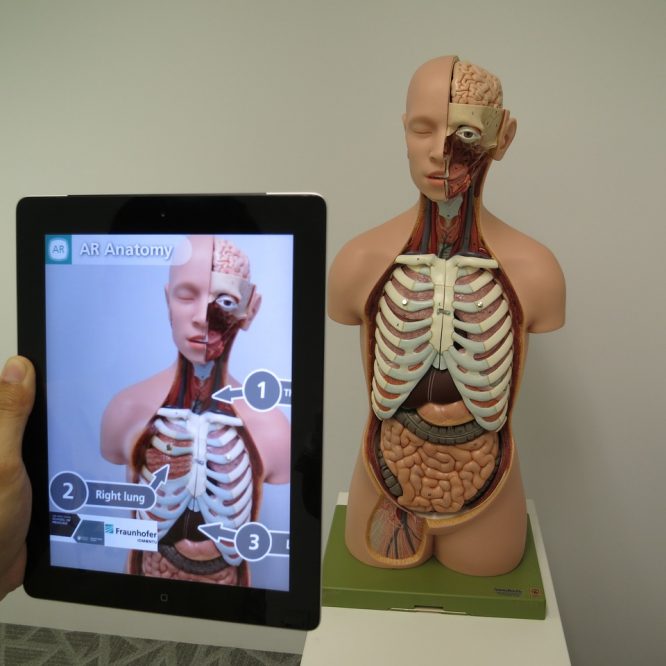

At the EGLAVATOR, we have created an innovative way to use mobile devices, augmented reality, and other technologies to take care of biohazard and medical waste. Our solution combines advanced technologies in a new venture will be called “Augmented Reality Biotech” or AR-BIO, that I will explain in the following sections.

AR BIOTECH – Augmented Reality Biotechnologies

AR BIOTECH is the spinoff company derived from EGLA CORP’s R&D and other collaborations with other partners, that lead us to the creation of a novel solution for biohazard waste management.

The main focus of this new AR company and its product is found in the use of an Augmented Reality (AR) interfaces that interact with a heating device that melts and eliminates contaminants. This process is then capable of efficiently and safely dispose biohazard and medical waste materials.

The heating device follows all CDC/EPA approved processes and its residual elements can be thrown out to any garbage can. Therefore, our solution removes the need for a specialized waste management pickup agreement, which could be expensive and medical waste is not disposed right away.

HOW IT WORKS?

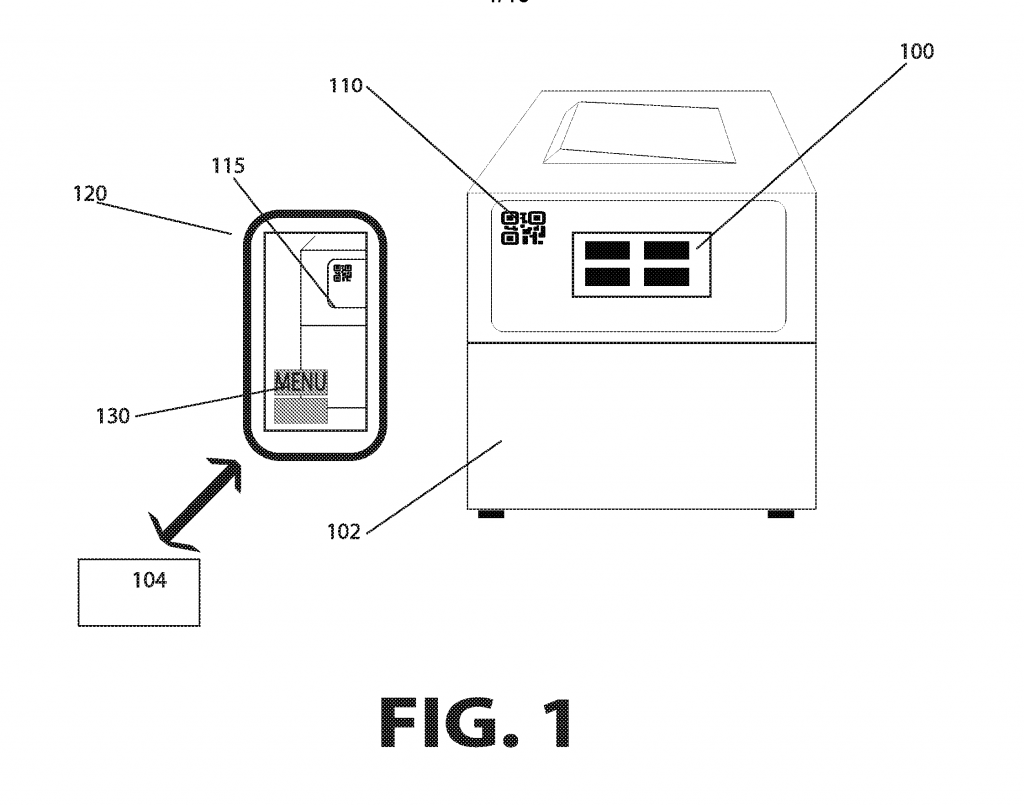

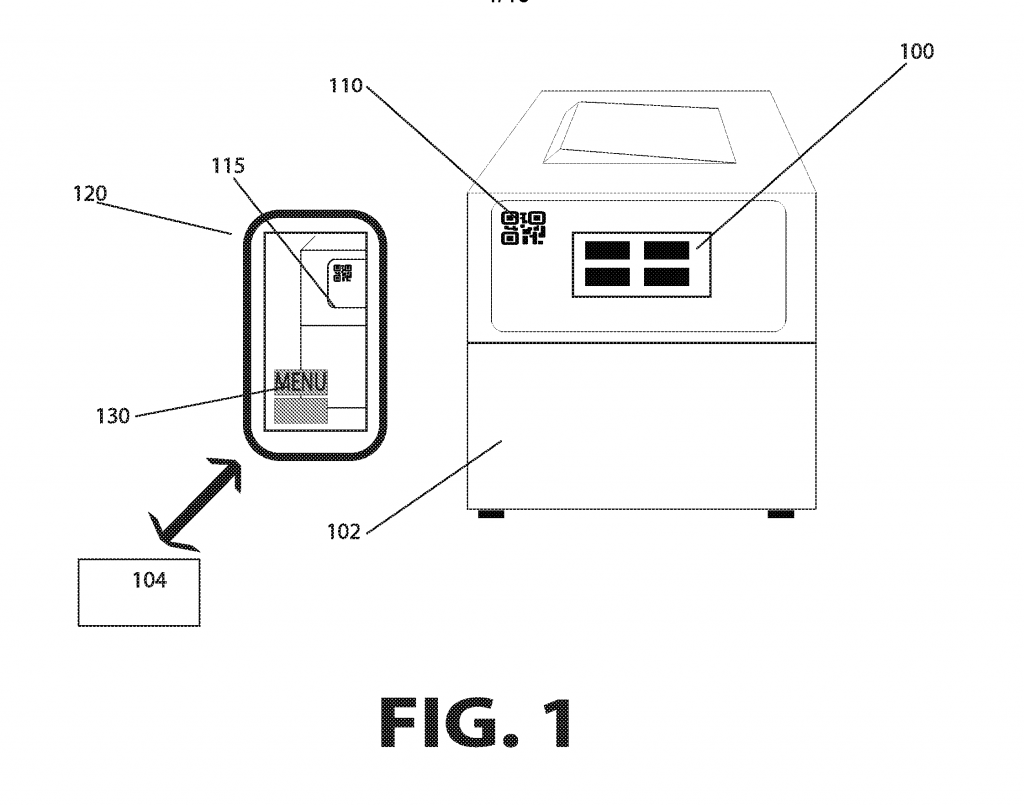

Our platform has two components: Mobile with AR and a Heating Device with intelligence connected to the Internet (Internet of Things). A cloud platform tracks the use of the unit, manages waste disposal events, and employs artificial intelligence to analyze data to safely control and automate the process of biohazard waste management. Now the biohazard and medican waste can be taken care of directly at a Dr’s office, ER, Pharmacy, Hospital or clinic, and done immediately and anytime.

Our platform and heating devices implement an environmentally friendly method that safely destroys sharps and reds, in a contactless or with minimum to no contact fashion. We achieve this by incorporating Augmented Reality interfaces to the process, and allowing control of a heating unit remotely.

Therefore, Biohazard waste management meets the metaverse with augmented reality interfaces & IOT – Internet of Things.

It is well known that hazardous materials can be highly contaminant and dangerous to handle by healthcare workers. Therefore, Augmented Reality (AR) tools are of great help to those workers in contact with needles, swabs, and any biohazard waste in a daily basis. Our technology allows biohazard and medical waste management to be safe, and completely controllable from a mobile phone, a tablet, or any “AR” Google solution..

Our solution includes a mobile application with “Augmented Reality” that interacts with our heating device with the biohazard materials being disposed. The heating devices heats a metal container for over 2.5 hrs at 400F. A health worker can then visualize the status of such process by pointing a mobile phone to the heating device that will overlay an augmented reality interface to the biohazard disposal procedure.

Therefore, once the 2.5hrs are completed the resulting heated block can be manipulated and thrown away, as all viruses, bacteria and others were eliminated.

Usually, we think that Augmented Reality (AR) is a tool only used to assist in teaching & learning by overlaying menus, labels, etc to enhance any learning experience, but rarely we see that AR is very helpful for control of other user interfaces, specially in the medical sector. In a way, our innovative technology brings the metaverse to reality and viceversa.

AR BIOTECH is a perfect fit for the metaverse and biohazard waste management

Our platform is a great use case whereby “Augmented Reality” is employed to control a potentially dangerous process, which is disposing of biohazards and medical waste materials.

The AR tool can also overlay temperate heat maps, animations, controls, time, reports, and updates from all sensors to handle this process safely.

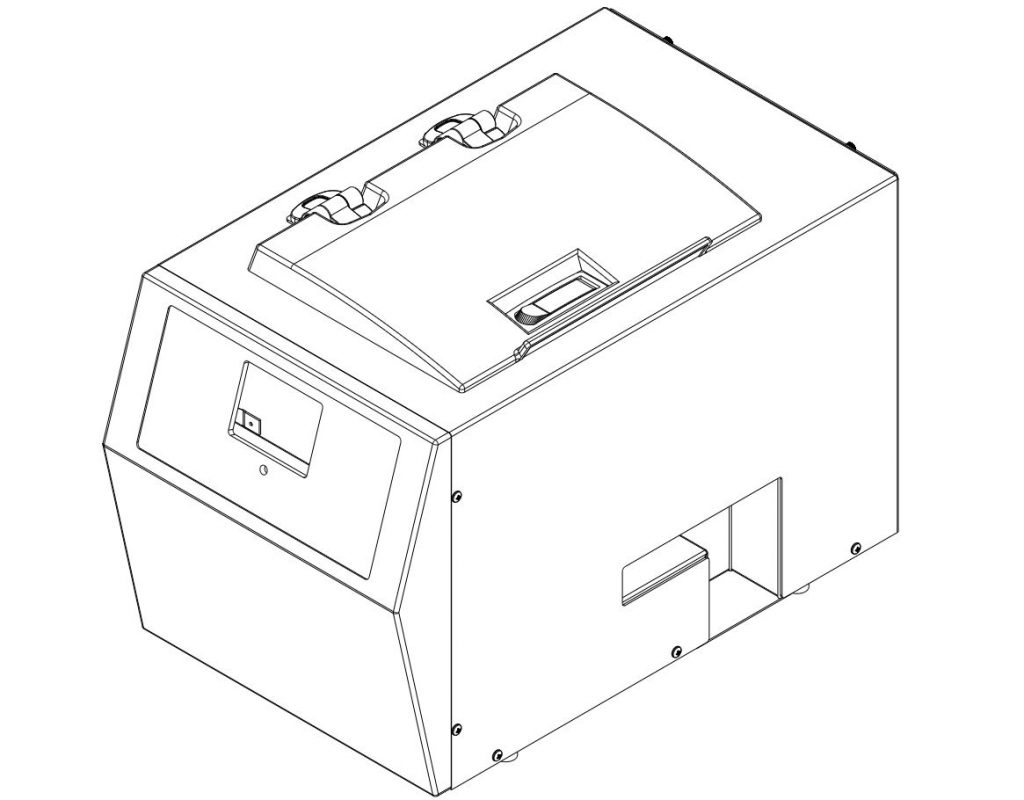

We manufacture the Device and metal containers that dispose Biohazard Material

The device on the left contains a heating element and a sealed crucible box with a filters that heats biohazard waste while at the same time tracks the entire process following strict CDC guidelines and ensures those are met.

The following animation shows the heating device that was built to load with needles and/or reds to be cleanly destroyed at any Dr’s, office, ER Practice, Hospital, Pharmacy, etc.

The heating device loads collector units, such as the one below, that contains a plastic spinner to hold all sharps (e.g. needles) or capture reds (e.g. swabs). The container is filled and are part purchased at a reasonable price per unit.

The CDC proposes several types of decontamination processes, but the one that caught my interest is “Moist Heat,” which basically consist in raising the temperature to 60″ at 80% humidity and that will be sufficient to kill H1N1 and other viruses like COVID-19.

Moist heat

Moist heat, consisting of 60°C and 80% RH caused minimal degradation in the filtration and fit performance of the tested FFRs [3, 9, 10]. Heimbuch et al. disinfected FFRs contaminated with H1N1 using moist heat, of 65°C and 85% RH, and achieved a minimal of 99.99% reduction in virus [14]. One limitation of the moist heat method is the uncertainty of the disinfection efficacy for various pathogens.

Source: https://www.cdc.gov/coronavirus/2019-ncov/hcp/ppe-strategy/decontamination-reuse-respirators.html

Patented Invention : Augmented Reality with Biohazard Device

We expect to get a patent on this process as we are in the last stages of the process.

The way my invention works is as follows:

In the cases of Covid-19 biohazard destruction can be controlled from your phone. A mobile phone downloads the control application that connects to a cloud-based platform where all the devices are controlled. All devices that destroy needles or clean masks are IOT-capable (Internet of Things). All IOT functions are exposed in a secured way to the device that contains contaminated products.

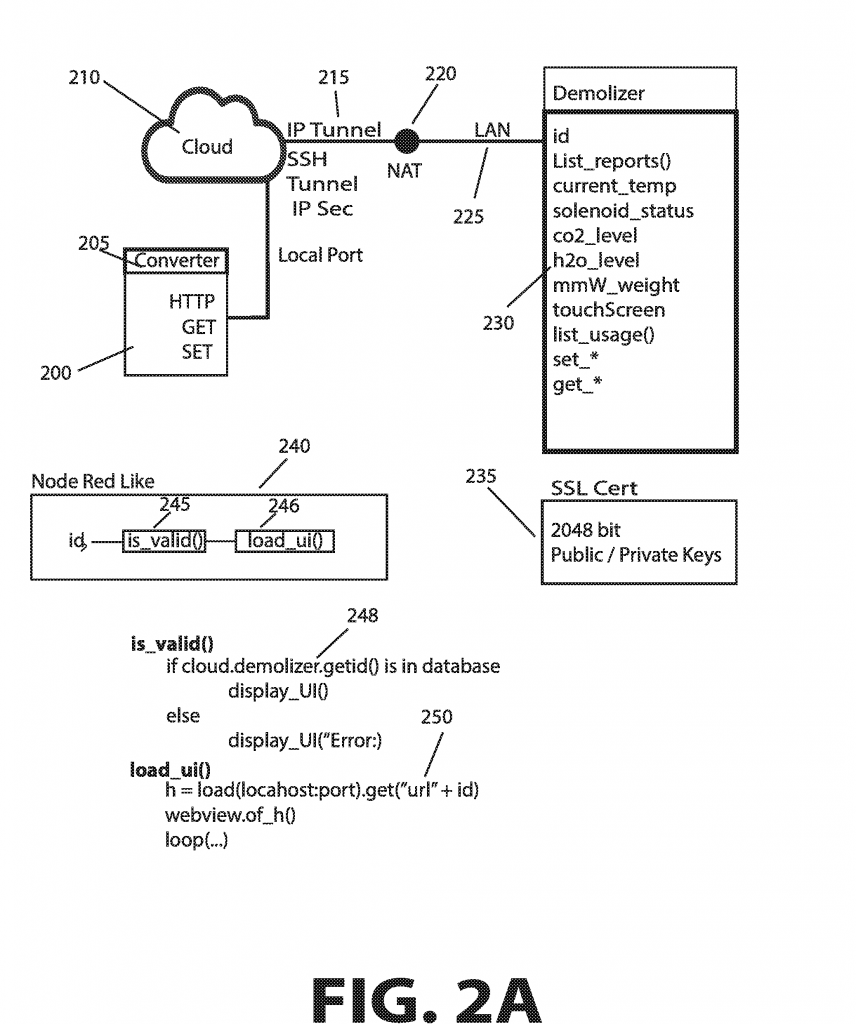

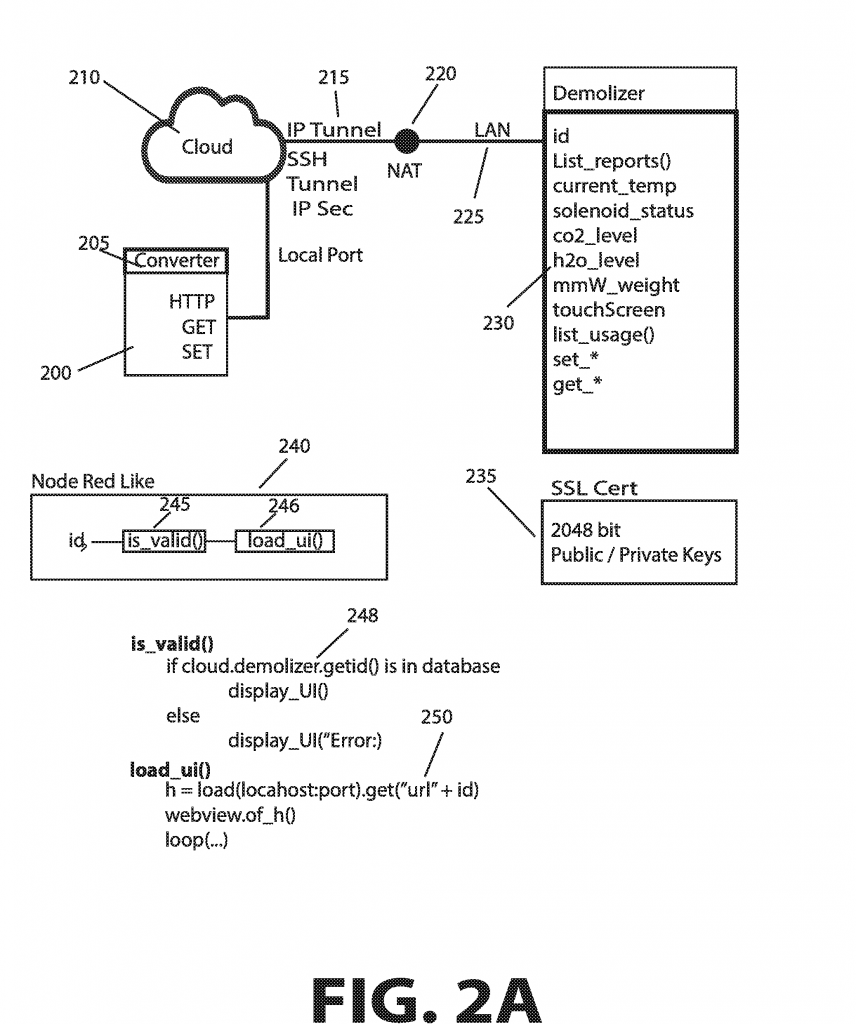

The cloud-based platform as shown in FIG 2A, has all the data and information created using an IP Secured tunnel with the information stored on device. Both the application at your mobile phone and the cloud are hence communicating to obtain information from the decontamination process.

Augmented reality icons can be shown and displayed with information on where things are, stop the process, or remotely update a nurse or a technician to handle a contamination process.

Scenarios & Use Cases

The number of utilization scenarios increases is mapped to devices that can clean but completely destroy “reds and sharps” at higher temperatures.

Usually, the process will enable using sensors and other tunneling techniques to handle other scenarios and detect other dangerous contaminants that could be generated during a process like this.

Availability, Licensing & Partnerships

We are planning to manufacture a new batch of devices by Q1, 2022 and make it ready for production by Q3, 2022.